Choosing the correct screw for your project is crucial for ensuring the structural integrity and longevity of your work. Whether you're embarking on a DIY home improvement project or working on a professional construction site, understanding the various types of screws and their specific applications can save you time, effort, and potential frustration. This guide will walk you through the essential factors to consider when selecting the right screw, ensuring your project is secure and successful.

1. Understanding Screw Anatomy

Before diving into the selection process, it's important to understand the basic anatomy of a screw. A screw typically consists of three main parts:

- Head: The top part of the screw, which can be flat, round, or oval. The head type determines the screw's appearance and how it sits on the material.

- Shank: The smooth, cylindrical part of the screw below the head. The shank’s diameter affects the screw’s strength and the size of the pilot hole needed.

- Thread: The helical ridge that wraps around the shank. Threads provide grip and pull the screw into the material.

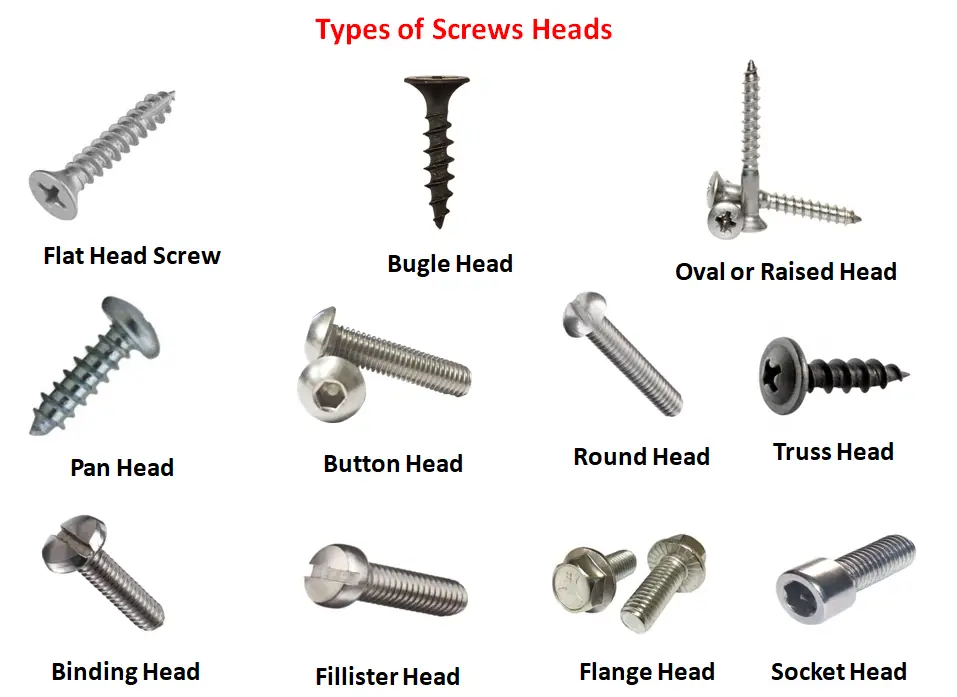

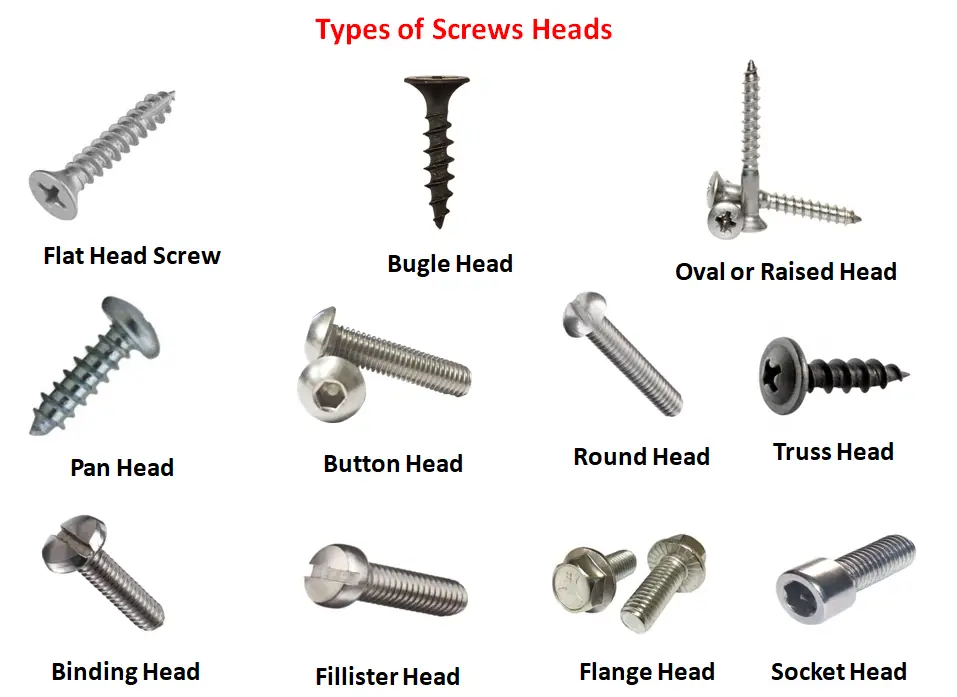

2. Types of Screw Heads

The screw head type is vital for both functional and aesthetic reasons. Here are some common types:

- Flat Head: Designed to sit flush with the material's surface, ideal for countersinking.

- Pan Head: Has a rounded top and a flat underside, providing a large surface area for a firm hold.

- Round Head: Similar to pan heads but with a more pronounced dome, often used where a decorative finish is desired.

- Oval Head: Combines the flat underside of a flat head with the rounded top of a pan head, useful for aesthetics and functionality.

3. Screw Drives

The drive type refers to the pattern on the screw head that determines the type of screwdriver or bit needed. Common drive types include:

- Slotted: A simple, straight line that requires a flathead screwdriver.

- Phillips: A cross-shaped drive that allows for greater torque without slipping.

- Torx: Star-shaped, providing excellent grip and reducing the risk of cam-out.

- Hex: A hexagonal recess requiring an Allen wrench, commonly used for furniture assembly.

4. Material Compatibility

Choosing the right screw material is crucial for the longevity and durability of your project. Here are some common materials and their uses:

- Steel: The most common material, offering strength and affordability. Suitable for indoor use where corrosion is not a concern.

- Stainless Steel: Highly resistant to rust and corrosion, ideal for outdoor and marine applications.

- Brass: Resistant to corrosion and often used in decorative applications due to its gold-like appearance.

- Aluminum: Lightweight and corrosion-resistant, suitable for applications where weight is a concern.

5. Thread Types

The thread type of a screw affects how it interacts with the material. Key thread types include:

- Coarse Threads: Provide strong holding power and are easier to drive into softer materials like wood.

- Fine Threads: Offer greater holding power in hard materials but can be more challenging to drive.

- Self-Tapping Threads: Feature a sharp point that cuts its own thread into the material, ideal for metal and plastic.

6. Length and Diameter

The length and diameter of a screw must be appropriate for the material thickness and the load it needs to bear. Here’s how to choose:

- Length: The screw should be long enough to penetrate the material adequately without poking through the other side. As a general rule, it should be at least twice the thickness of the material being fastened.

- Diameter: Thicker screws offer greater strength but require larger pilot holes. The diameter should match the material’s density and the project’s requirements.

7. Application-Specific Screws

Certain projects may require specialized screws designed for specific applications. Examples include:

- Wood Screws: Designed for wood, featuring coarse threads and a tapered shank.

- Drywall Screws: Thin screws with fine threads, designed to penetrate drywall without damaging it.

- Masonry Screws: Made from hardened steel with deep threads for gripping into brick, concrete, and stone.

- Deck Screws: Coated to resist corrosion, ideal for outdoor decking projects.

8. Environmental Considerations

The environment where the screw will be used plays a significant role in its selection. Factors to consider include:

- Humidity: In high-humidity environments, choose stainless steel or coated screws to prevent rust.

- Chemical Exposure: For areas exposed to chemicals, use screws made from materials resistant to corrosion.

- Temperature: Extreme temperatures can affect screw performance. Opt for materials that can withstand the specific conditions of your project.

Conclusion

Selecting the correct screw for your project involves considering various factors, including the screw's head type, drive type, material, thread type, length, and diameter. By understanding these elements and how they interact with your project's materials and environment, you can ensure a secure and durable result. Remember, the right screw can make all the difference in the success and longevity of your work.