In today’s fast-paced and competitive manufacturing landscape, efficiency, precision, and reliability are paramount. At the heart of many production facilities lies the packaging line—a critical component that ensures products are properly sealed, labeled, and ready for distribution. As technology evolves, so does the sophistication of

packaging line control systems, revolutionizing the way manufacturers operate. In this article, we explore the advancements in packaging line control and how they are transforming production processes.

The Importance of Packaging Line Control

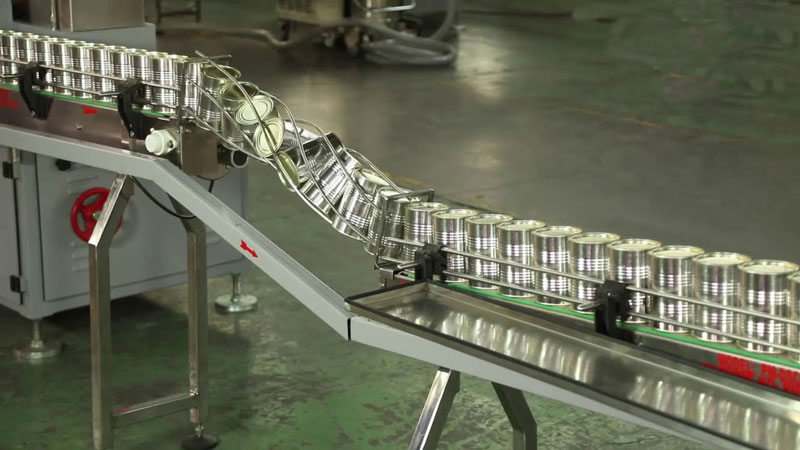

Packaging line control is the management of various processes and equipment involved in the packaging of products. It encompasses everything from filling and sealing to labeling and palletizing. Effective control of these processes is essential for maintaining product quality, minimizing waste, and ensuring operational efficiency. With consumers demanding higher standards and regulatory bodies imposing stricter guidelines, the role of

packaging line control has never been more critical.

Advancements in Packaging Line Control Technology

Recent technological advancements have significantly enhanced the capabilities of packaging line control systems. These innovations are enabling manufacturers to achieve greater precision, speed, and flexibility in their operations.

1.Automation and Robotics

One of the most transformative trends in

packaging line controlis the integration of automation and robotics. Automated systems can perform repetitive tasks with high precision and consistency, reducing the likelihood of human error. Robots equipped with advanced sensors and machine learning algorithms can adapt to different packaging formats and materials, increasing the versatility of the production line.

2.Internet of Things (IoT)

The Internet of Things (IoT) is another game-changer in packaging line control. IoT-enabled devices can collect and transmit real-time data on various parameters such as temperature, humidity, and machine performance. This data can be analyzed to optimize operations, predict maintenance needs, and prevent downtime. IoT connectivity also allows for remote monitoring and control, enabling managers to oversee production lines from anywhere in the world.

Artificial Intelligence (AI) and Machine Learning

AI and machine learning are revolutionizing packaging line control by enabling predictive analytics and intelligent decision-making. AI algorithms can analyze historical data to predict potential issues and recommend corrective actions. Machine learning models can also optimize packaging processes by identifying patterns and trends that humans might overlook. These technologies lead to more efficient use of resources and higher-quality products.

1.Advanced Sensors and Vision Systems

The use of advanced sensors and vision systems has greatly improved the accuracy and reliability of packaging line control. High-resolution cameras and optical sensors can detect defects, misalignments, and inconsistencies at a microscopic level. This ensures that only products meeting the highest quality standards proceed down the production line, reducing waste and enhancing customer satisfaction.

Benefits of Modern Packaging Line Control

The adoption of advanced packaging line control technologies brings numerous benefits to manufacturers. These include:

1.Enhanced Efficiency

Automation and real-time data analysis streamline operations, reducing bottlenecks and increasing throughput. This leads to faster production cycles and shorter lead times, allowing manufacturers to meet customer demands more effectively.

2.Improved Quality

With precise control over every aspect of the packaging process, manufacturers can ensure consistent product quality. Advanced sensors and AI-driven quality checks catch defects early, minimizing the risk of faulty products reaching consumers.

3.Cost Savings

Optimized operations and reduced waste translate to significant cost savings. Predictive maintenance minimizes downtime and extends the lifespan of machinery, while efficient resource use lowers operational expenses.

4.Flexibility and Scalability

Modern packaging line control systems are highly adaptable, allowing manufacturers to switch between different product lines and packaging formats with ease. This flexibility is crucial in today’s market, where consumer preferences and trends can change rapidly. Additionally, scalable systems can grow with the business, accommodating increased production volumes without major overhauls.

The Future of Packaging Line Control

As technology continues to evolve, the future of packaging line control looks promising. Emerging technologies such as augmented reality (AR) and blockchain are set to further enhance transparency, traceability, and efficiency in packaging operations. AR can provide real-time assistance to operators, guiding them through complex tasks with visual overlays. Blockchain can ensure secure and transparent tracking of products throughout the supply chain, enhancing trust and accountability.

In conclusion, advanced packaging line control systems are revolutionizing the manufacturing industry. By leveraging automation, IoT, AI, and advanced sensors, manufacturers can achieve unprecedented levels of efficiency, quality, and cost savings. As we look to the future, continued innovation in packaging line control will be essential for staying competitive in an ever-evolving market. Embracing these technologies is not just an option; it is a necessity for manufacturers aiming to thrive in the modern era.

.

LANDPACK would be your reliable supplier of

packing line and

filling machines line, which obtains many kinds of

certificate of the packing machine issued by authority agency.