| Type |

LDSP-160 |

LDSP-160Y |

LDSP-210 |

LDSP-260 |

| Bag Type |

3-side, 4 side sealing bag, Doypack, M Shape Pouch, Zipper Pouch, Stand Up Pouch, Stand Up Pouch With Hole, Kraft Paper Bag, Side Gusset Bag etc. |

| Bag Size |

110-230mm*80-160mm(L*W) |

70-100mm*110-230(L*W) |

100-210mm/110-320mm(L*W) |

100-260mm/110-320mm(L*W) |

| Filling Range |

10g-100g |

10g-100g |

10g-1kg |

10g-3kg |

| Packing Speed |

20-45bags/min(speed is determined

by the product filling quantity) |

25-50bags/min(speed is determined

by the product filling quantity) |

20-50bags/min (speed is determined

by the product filling quantity) |

20-50bags/min (speed is determined

by the product filling quantity) |

| Machine weight |

800KG |

800KG |

900KG |

1000KG |

| Total Power |

2.0KW |

2.0KW |

2.0KW |

2.0KW |

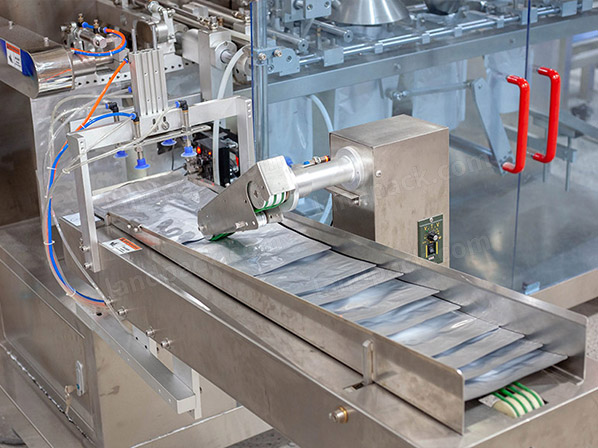

| Work Flow |

1.Giving bag 2. Pick up the bag(coding) 3.Open the bag up and down 4.Filling

5.Heating sealing 6.Output of product |

| Dimensions |

1750mm X 1285mm X 1360mm(L*W*H) |

2140mm X 1366mm X 1360mm(L*W*H) |

2140mm X 1366mm X 1360mm(L*W*H) |

| Collocation |

Screw metering,screw elevator |